Suddenly out of a job and wondering how to make a living, Charlie Pearson developed his woodworking hobby into a full time, lifetime career. Today, at 77 years young, he’s making a great living and doing excellent work as “the oldest cabinetmaker in Warren County, Tennessee.”

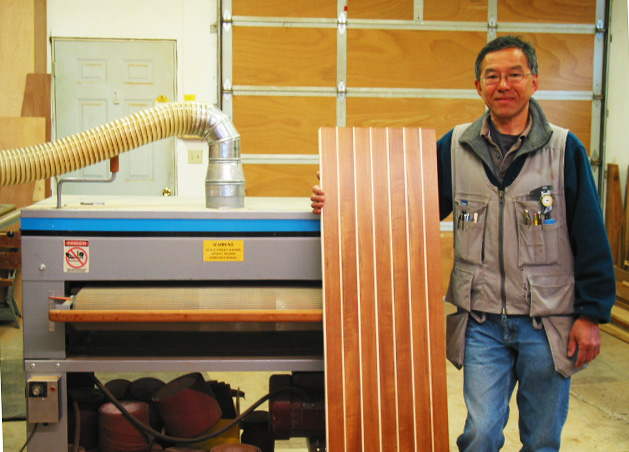

Here’s Charlie Pearson in his shop running crown molding on one of his four Woodmaster Molder/Planers. When his employer closed their doors, Charlie got serious about woodworking and the rest took care of itself.

Editor notes: Charlie owns 4 Woodmasters. Those in this photo are his oldest ones — 28 years old and still going strong. These older models were painted grey and did not have dust collections hoods. See what NEW Woodmasters look like.

“I started woodworking as a hobby in about ’73. I started building furniture, reproductions of dry sinks, washstands, desks, poster beds, chest of drawers, tables, oak and cherry tables, and all those kind of things. I managed a grocery store full time and when it closed in ’84, I had to get a job somewhere and I’d never done a resume.

I started making custom doors and raised panels for cabinetmakers. Then I figured out that since I was doing what they did, I could do the whole cabinet. So in the late ‘80’s, I started building cabinets and the business started growing. I’ve expanded my shop five times to today’s 10,000 square feet. I have over 200 power tools including four Woodmaster Molder/Planers.

When you get into woodworking, you have to be versatile. I need the Woodmaster molding machines to make all kinds of trim. I’ve got many stock molding knives and probably 15 custom cutters besides.

4 Woodmasters – 4 full-time setups

Charlie does beautiful work. This dream kitchen is just one example of how Charlie has made a name for himself. He tells us he never had training; he learned by doing.

If you’re going to make a living in woodworking, you have to figure out how to do custom work AND maximize production. Your work has to be quality, but you have to figure out how to be productive. You can do that by adding Woodmasters and mounting the cutters you’re going to use so you don’t have to spending time changing them over. It’s more accurate that way, too, when you leave them set up. You don’t have to worry about not being right when you use them.

Here’s how I use all four of my Woodmasters: I have them all set up and I don’t change cutters. I don’t have any down time changing cutters. I do so many different kinds of things, I use all of them within a month’s time because of the different trims they’re set up to do. I can do five different crown molds; three without changing cutters. Some of my machines have more than one cutter on them at a time. As long as it’s balanced it’s not hurting anything. One Woodmaster is mounted with a back cutter, a crown mold cutter, a shoe mold, and a 1-13/16” bead mold knife. Another machine has 5-3/4” mold I use on mantles, a cove mold, and a shoe mold. I’m set up to make 4-5/8” crown mold; 2-3/4” crown mold; shelf edging; a special mold I use around the bottom of cabinets; 1-13/16” bead mold. I use them all.

SAVE BIG NOW on Woodmaster Drum Sanders! – sale prices, online specials

SAVE BIG NOW on Woodmaster Molder/Planers! – sale prices, online specials

His 28-year old Woodmaster’s still going strong

I’ve never had any trouble with any Woodmaster, even the one that’s 28 years old. Woodmaster refers people to me to talk about my machines. I tell people that the years I’ve had them, I’ve never had problems with them. They come with a 5-year warranty. I’ve never had any problems with any of them.

There’s always demand for high quality woodworking. Charlie tells us his business is strong, even in today’s economy. The quality of his work is the reason he’s always busy.

The advantage of having Woodmaster is it’ll make high quality molding at low cost. My brother had an expensive, high-speed molding machine that cost $17,000. See, I can buy half a dozen Woodmasters for that.

I hadn’t had training in woodworking. My brother did woodworking – I worked with him a little and learned how to make raised panel doors. I just picked it up through studying. I just learned it thorough the years. I chose Woodmaster because my brother had one. He had gone from that expensive molding machine to a Woodmaster because it was more versatile. You buy one Woodmaster and you want more!

Charlie’s business plan? Quality, efficiency & treat people right

I’ve got three people working with me part time. When the economy was good, we had seven people. We’d have seven or eight cabinet jobs going at the same time. Things have slowed down but I’m still above water. I don’t have any trouble making good money because I manage my costs and my workflow.

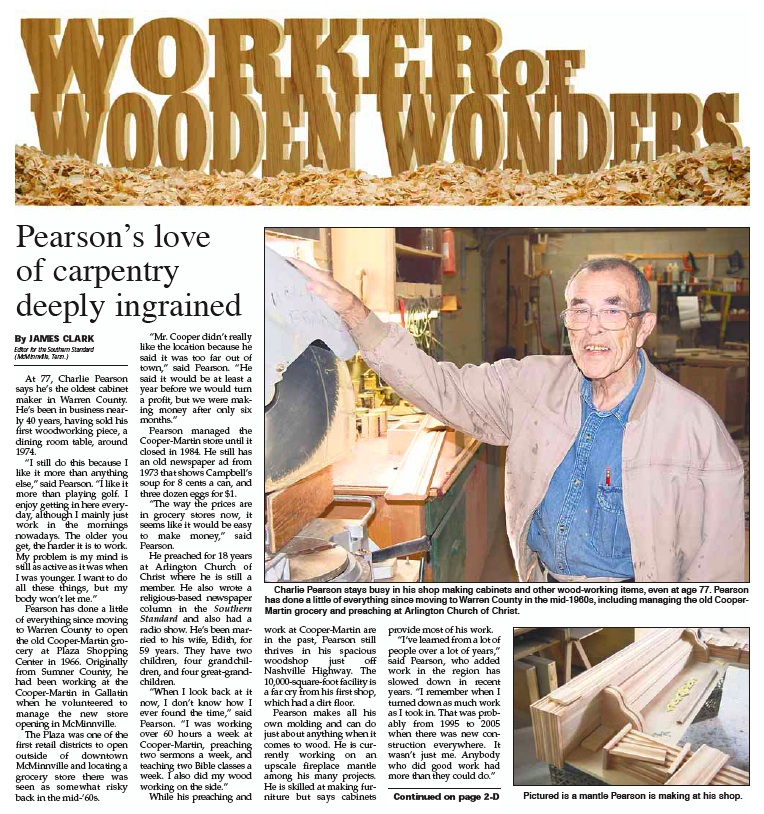

Charlie’s in the news! Here’s an article about him published recently in his local newspaper, The Southern Standard, of McMinnville, TN. Courtesy Southern Standard.

My rule of thumb is your cost of materials for a job shouldn’t be more than half what you charge. Materials you buy shouldn’t run over 50% of what you charge. Half of what you charge is for your material and the other half is labor, operations, and overhead. If you’re doing real detailed work, materials should be less than half what you charge.

My philosophy? Do quality work and get it right the first time. My advice for others: get quality tools and treat others like you’d like to be treated and business will take care of itself. The advice I give younger guys is, don’t work for the money; work because you want to do a good job and you won’t have to worry about the money part.

Don’t think too long.

If you’re thinking about getting a Woodmaster, don’t think too long, just go ahead and buy one. It’s the best value. You can buy ‘em cheaper but it will cost you more in the long run because it doesn’t have the quality Woodmaster does. And the Woodmaster company’s been real good. Any problems I’ve had, they’ve taken care of them.

When you build something, it’ll be there for hundreds of years. The cabinets I build will last that long. I built a mantle for a lady and she said, ‘Mr. Pearson, will you sign the back of it?’ I asked her why and she said, ‘Someone may tear this house down 100 years from now.’ I told her I’d put my phone number there on the back and when someone tears it down in a hundred years, they can call me!’”

— Charlie Pearson, Woodmaster owner, McMinnville TN

See more of Charlie’s work, and read more about him on his website, www.kpcabinets.com

SAVE BIG NOW on Woodmaster Drum Sanders! – sale prices, online specials

SAVE BIG NOW on Woodmaster Molder/Planers! – sale prices, online specials

QUESTIONS? COMMENTS?

3 WAYS we can help you!

- Call us TOLL FREE 1-800-821-6651

• Email us info@woodmastertools.com

• Connect with us on Facebook