Woodmaster owner, Donald Accomando, shared his success secret with us recently. “Many woodworkers have the same skills I do,” he told us. “But their equipment doesn’t let them work efficiently so they can’t turn the product out.” Donald’s secret? “Choose equipment that produces high quality results with high efficiency.”

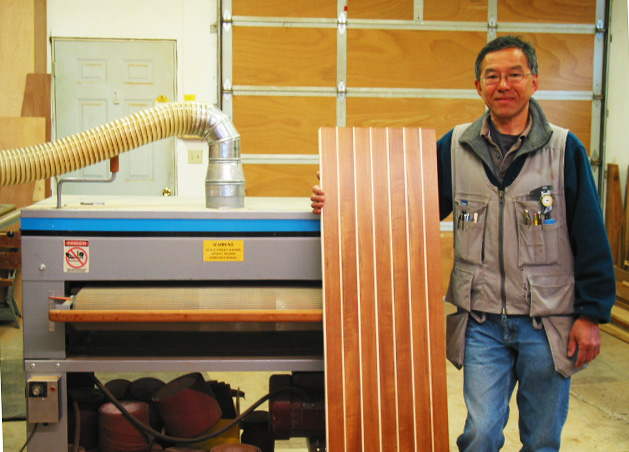

Here’s Donald with his 50″, double-drum, 5075-X2 Woodmaster Drum Sander. His wife, Janet, stands behind the sander. Donald tells us, “Janet is my Chief Inspector and Quality Control Supervisor!” Photo by Donald’s former student, Julie Prayer.

“I buy equipment that will make my shop more efficient and I believe dedicated machinery that does one thing perfectly is best. My advice for anyone thinking of getting a drum sander is to get the best you can afford that fits the size of your business.

My main point? I choose the best equipment that helps me turn out quality work with high efficiency. Other cabinetmakers are as good at woodworking as I am but their equipment doesn’t increase their efficiency. So they can’t put the product out. Woodmaster helps me work efficiently.

Here’s a spectacular example of Donald’s work. “I recently did this complete kitchen,” he tells us. “The wood is all Australian Liptus. The homeowner wanted a natural finish to offset the decor of their home. I achieved this by using a 3 ml coat of conversion varnish.” Photo by Donald’s former student, Julie Prayer.

30 years with no advertising, no website, not even business cards.

I make custom cabinets, mostly residential, all high quality work. I’ve been doing this for over 30 years and it’s always been fairly steady. My work has been all referral. I don’t advertise and I don’t have a website. I don’t even have business cards. I don’t have to.

Early words of wisdom stuck with him.

When I was in college, I worked in a cabinet shop where I picked up the cabinetmaking trade. It was a good-sized, 40-man production shop that built high end, quality cabinetry. I got a well-rounded education there. Sometimes I’d make drawers, sometimes face frames, always something different. When I left that job, the owner told me, ‘Whatever woodworking you do, always buy the best equipment.’ That’s always struck with me.

I started making cabinetry on my own, and I kept buying better equipment. My first shop was an old garage with an 8’ ceiling which is tough for tall cabinets. The shop I have I have now is over 4,000 sq. ft. The equipment I’ve acquired over the years is pretty much top of the line. It’s a serious shop.

SAVE BIG NOW on Woodmaster Drum Sanders! – sale prices, online specials

SAVE BIG NOW on Woodmaster Molder/Planers! – sale prices, online specials

Donald Accomando has a shop to die for! It’s over 4,000 sq. ft. with a high ceiling, and it’s packed with top-of-the-line woodworking machinery that gives him excellent results and high maximum working efficiency. His sander? A Woodmaster Drum Sander, of course. Photo by Donald’s former student, Julie Prayer.

An average new home around here will have 40 to 75 doors in it. I’ll make doors for the kitchen, two or three bathrooms, laundry room, entertainment center, and more — it’s a lot of doors. I buy doors through a custom door company but 90% of the time I make the doors. I have eight shapers that are dedicated to making doors.

Hand-sanders are inefficient tools for finish sanding

When I first started making doors, I used conventional hand-held belt sanders. These were good hand sanders — Porter Cable. But they weren’t efficient tools for that job. You grind down the high spots, air sand the rest, and you’ve ended up sanding multiple times with multiple sanders. To sand that many doors that way would take two guys probably 10 hours. You’d do a lot of hand sanding and you still wouldn’t get the door dead-flat.

Wide belt sanders? Fussy, expensive, “wavy” results.

My first sander was a used vertical wide belt sander with a 30” wide belt. It did an OK job although, unlike the Woodmaster Drum Sander, the pressure on the platen was controlled pneumatically. A lot of times, the panel or door you put through would end up with a bit of wave or ripple to it. There were other little things. It went out of adjustment and it wasn’t wide enough.

I like drum sanders. I had a big vertical belt sander. The giant ones cost three times more than a drum sander. They’re a little faster but the one I had was too small and I was always dicking around with adjustments. It wouldn’t make doors flat. A drum sander – when something goes through it, it comes out flat. Everything that goes through the Woodmaster comes out flat. It just works better. It works every time and you don’t have to fool with it. Price is a consideration, too. At the time I bought, new wide sanders were probably $15,000 – $25,000 and the Woodmaster was under $5,000.

This gorgeous stone-topped kitchen island makes an outstanding focal point in this showcase kitchen. And it makes food preparation convenient, too. Note the fully functional sink. Photo by Donald’s former student, Julie Prayer.

Woodmaster: “Everything comes out perfectly flat.”

The next sander I bought was a Custer, similar to the Woodmaster except it was not as heavy. The aluminum drums didn’t have the mass that Woodmaster’s steel drums have. The bed wasn’t as sturdy as Woodmaster’s, either. It was OK, but it just wasn’t heavy enough. So I sold that and got my first Woodmaster Drum Sander — a 38” double-drum 3875-X2 — about 12 to 15 years ago. The only thing I’ve ever replaced is the starter switch. What I liked about the Woodmaster from the get-go is it’s slightly slower than a wide belt, and everything comes out perfectly flat. I could do 75 doors in an hour and a half vs. 10 hours. And the doors come out with more precision.

Occasionally I’ll get 4’ face frames so I bought the 50” double-drum 5075-X2 Woodmaster which I love! It came with a 7-1/2HP motor. It’s a simple machine but everything on it is heavy duty. It’s a better machine: you never have to worry about parts breaking. There are lots of imports that initially look good but just don’t hold up. I still prefer Woodmaster. If I had to buy another one, I would.

“I prefer Woodmaster’s Double Drum Sanders.”

Woodmaster has both single and double drum sanders. I prefer the double drum. I can put 80-grit on one drum and 100, or 120, or 150-grit on the second. You can put different grits on the drums and sand with precision. I have my 5075-X2 set up with 80-grit on the infeed drum and 100 or 120- grit on the outfeed drum. That works for 90% of the work I do — doors, predominantly.

Another thing I like about the Woodmaster is the way the paper fastens to the drum with Velcro®. Other drum sanders have spring-loaded paper tensioners that are difficult to use. With Woodmaster’s system, the paper fits a lot better and changing papers is not a big issue. Woodmaster has an adjustable feed rate that others don’t and the feed-belt is heavier, too. The bearings are heavy, the motor’s heavy.

“Imports just don’t hold up.”

There are so many imports out there that just don’t hold up. For example, I had a 2HP Grizzly® dust collector hooked up to a $12,000 edge bander. The Grizzly® motor failed within a year and the local motor repair guy said he couldn’t fix it for what you’d buy a new one for. So I bought a dust collector from you guys – from Woodmaster. That motor has worked for 15 years.

An outstanding kitchen like this one deserves more than the traditional lazy susan in the corner. Donald has maximized storage space while creating a unique and space saving corner storage solution with angled drawer faces. Photo by Donald’s former student, Julie Prayer.

Price/Value Relationship

I’d look at Woodmaster first. It’s a real good value. Take Performax® sanders for example. They’re $2,500 and they’re just a big arm with a sanding head on it. They say you can sand half the width of your workpiece, then flip it around and do the other half. That doesn’t work that well. For a little more money, you can buy a real drum sander that’ll do the job well. Woodmaster just flat out works.

Most of my equipment is from Austria, Germany, or Italy. But I’d never buy any drum sander other than Woodmaster. In my experience, the Woodmaster Drum Sander does what it’s supposed to do and you don’t have to fool around with it. You can buy a wide belt but a wide belt the same size as the Woodmaster Drum Sander I have would cost you at least $25,000. Then you need the power to run its 10 or 15HP motor. Or you can pay $6,000 for a Woodmaster. It holds up and works better.

“The guys I talk to at Woodmaster build the machines.”

From a service point of view, Woodmaster’s great. Anybody you talk to there, they know their machines. Whatever I need to be satisfied, they do it. I wanted a longer power cord; they just did it for me. Other companies would say, ‘You’ve got to do that yourself’ and blah blah blah. I’ve talked to other salespeople for other products and, basically, they’re just reading the brochures. The guys I talk to at Woodmaster actually build the machines.

Simple & dependable

I like quality machinery and that drum sander is the heart of all my finish work. It has to be dependable and Woodmaster is. The edge bander I have is the most complicated machine I’ve ever had. It has probably 15 micro-switches in it. To have it serviced costs $2,000. I don’t have that problem with my Woodmaster Drum Sander!”

— Donald Accomando, Cabinet Maker, Woodmaster Drum Sander Owner, McArthur CA

SAVE BIG NOW on Woodmaster Drum Sanders! – sale prices, online specials

SAVE BIG NOW on Woodmaster Molder/Planers! – sale prices, online specials

QUESTIONS? COMMENTS?

3 WAYS we can help you!